tech-manufacturing

Reduction in manual

data monitoring

Increased output

Reduction in Defects

per hundred unit

Decrease in machine

down time

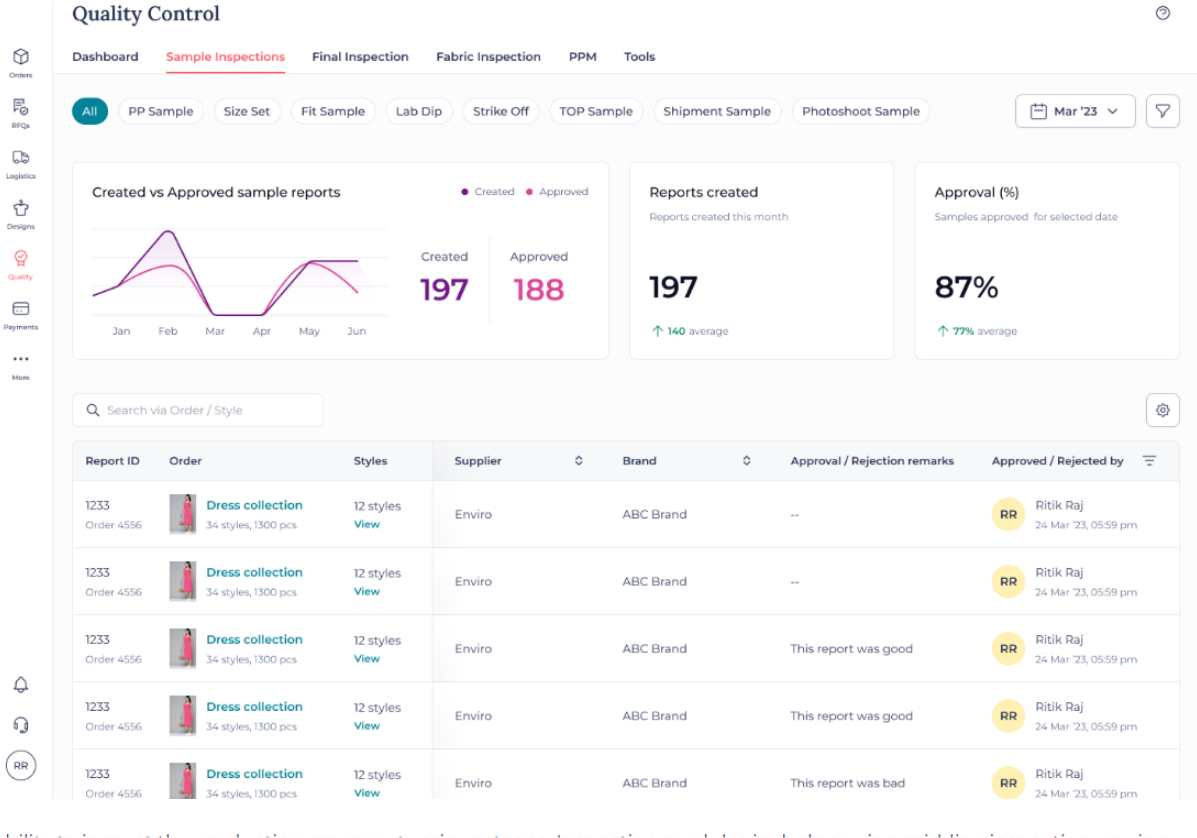

OUR BUYER-DRIVEN Quality Assurance Project Plan

STREAMLINING

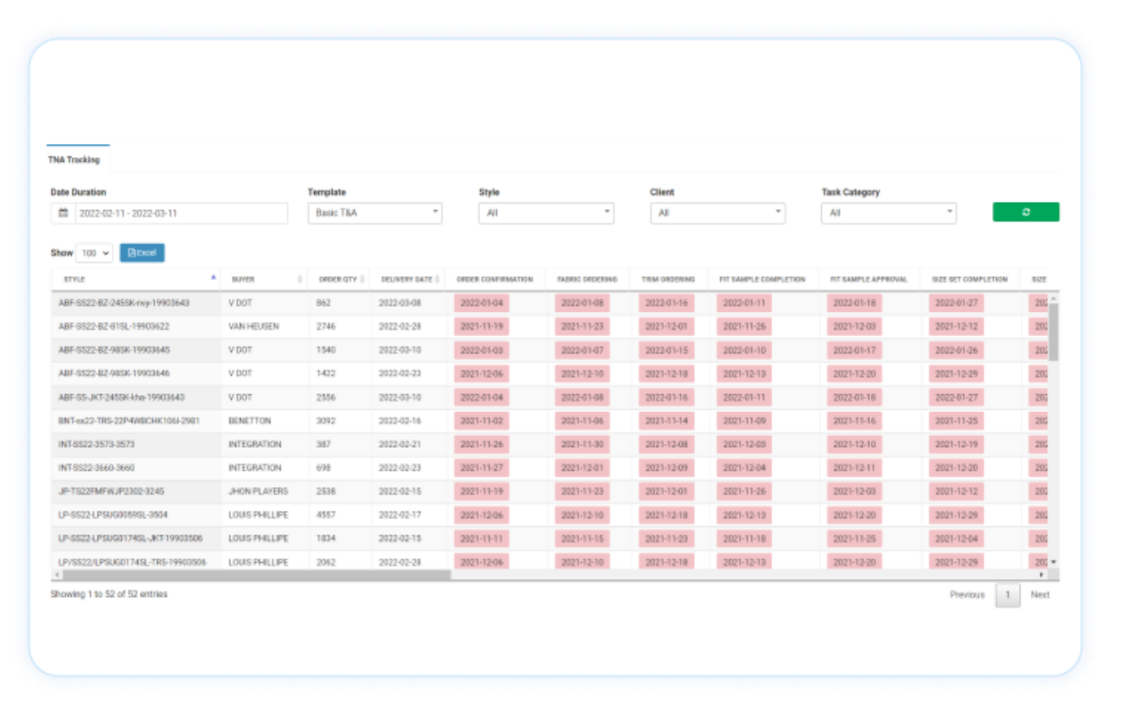

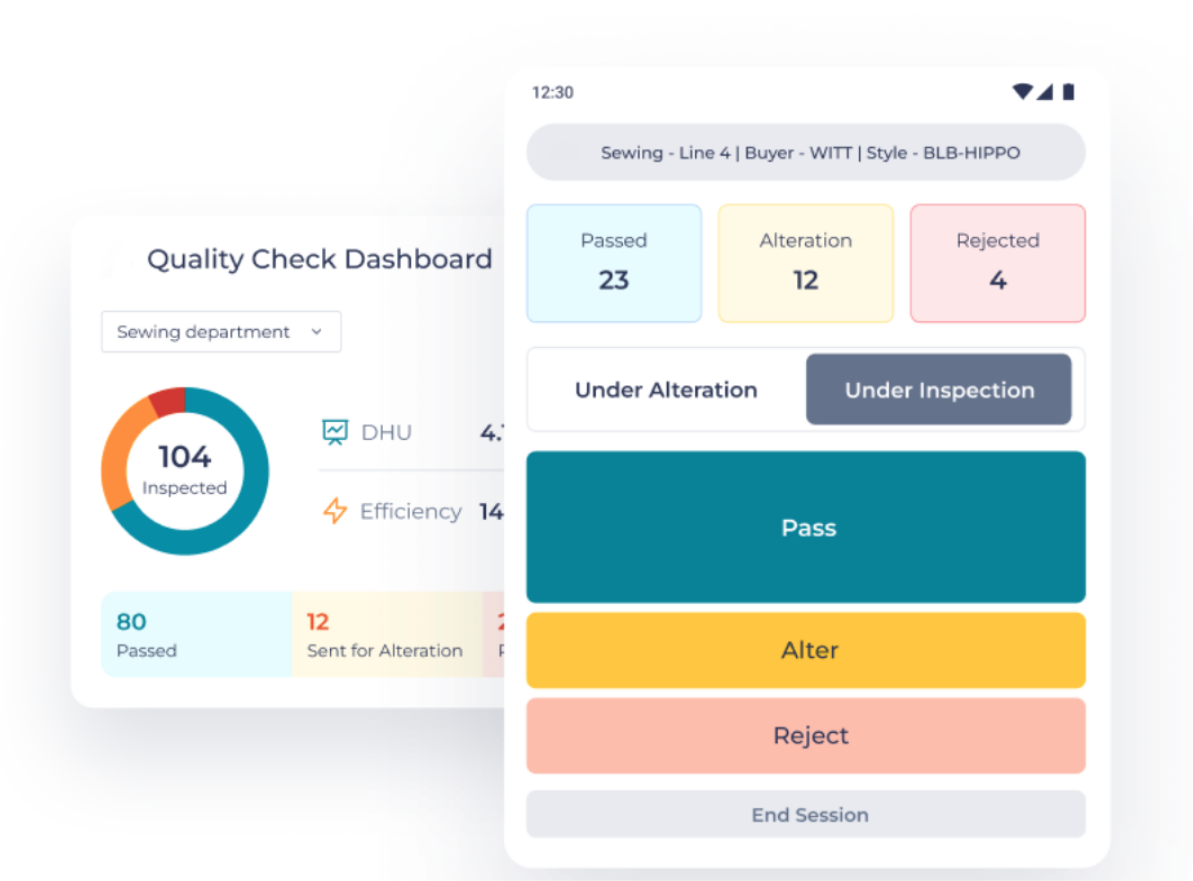

Our Quality Assurance Project Plan (QAPP) is Buyer- driven and highly consumer centric. It all comprises of a tablet and LED Screens planted on every production line to monitor and analyse the data. It has the following benefits-

PASS THROUGH THE CLOUD OF OPACITY-

Our QAPP ensures increased transparency, with data automation done per minute basis.minimised errors-

Due to digitalization of data and less human intervention, errors and internal failure can be avoided/minimised.BETTER CONTROL & EFFICIENT MANAGEMENT

Live status of work orders, progress of work and machine utilisation.proactive quality supervision

Monitoring quality parameters at every stage, identifying deviations, implementing corrective actions and ensuring compliance adherence.smart manufacturing- backed by our qapp

Optimizing factory data at each stage of the production process-

This can turn out vital for achieving optimal efficiency and productivity. By meticulously analyzing and optimizing the data at each stage, we can identify potential bottlenecks, make informed decisions, and implement strategic improvements.

Reducing internal quality failures next to negligible-

With the implementation of QaPP, we noticed significantly decrease reworks, paperwork, and we could effectively analyse quality control and production performance. Consequently, our managers witness enhanced production optimization within a month of adopting QaPP.

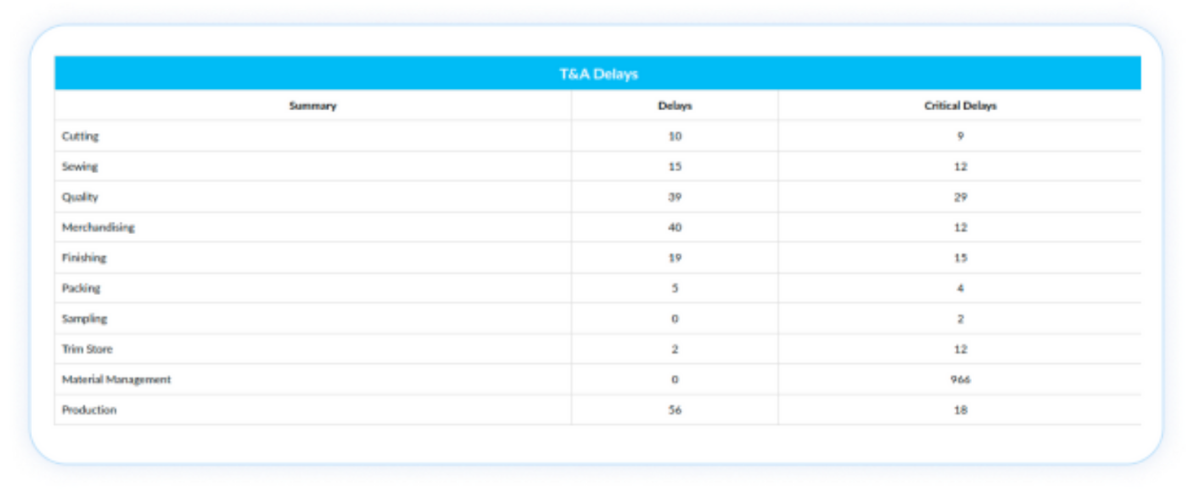

Access to wide range of metrics for a comprehensive understanding -

These metrics encompass various aspects such as the total number of units inspected, defects per hundred units, units undergoing alterations, units that have passed quality checks, hourly output, rejected items, and hourly line efficiency percentage.

Ability to inspect at various stages -

These modules encompass various stages such as mid-line inspection for sewing, end-line inspection for sewing, AQL audit for sewing, mid-line inspection for finishing, end-line inspection for finishing, and AQL audit for finishing. This inspection framework allows manufacturers to ensure quality standards are met consistently throughout the production journey.

Our QAPP has been a boon. Efficiency has increased significantly and it has boosted the output as well. Due this we have rolled it out in our other factories as well. We believe in having a data driven company which is very much in contrast to how we actually started i.e as a traditional manufacturer. To sum up we would say say we have made our company “future proof”.

unlocking efficiency through our Enterprise resource planning software

Our ERP offers the opportunity to modernize the entire supply chain, resulting in reduced operational costs. By leveraging our ERP system, we have enhanced our production processes, achieving greater efficiency in operations.

Centralised connection amongst all channels

monitoring goods en route

Automated inventory management

generating precise and reliable reports

predictive modeling to forecast future trends

enhanced output